CYGNUS DIVE UNDERWATER GAUGE

WRIST-MOUNTABLE UNDERWATER THICKNESS GAUGE

With its bright, very large, AMOLED display the Cygnus DIVE is simple to operate, providing accurate and reliable thickness measurements, underwater. Depth rated to 300 metres.

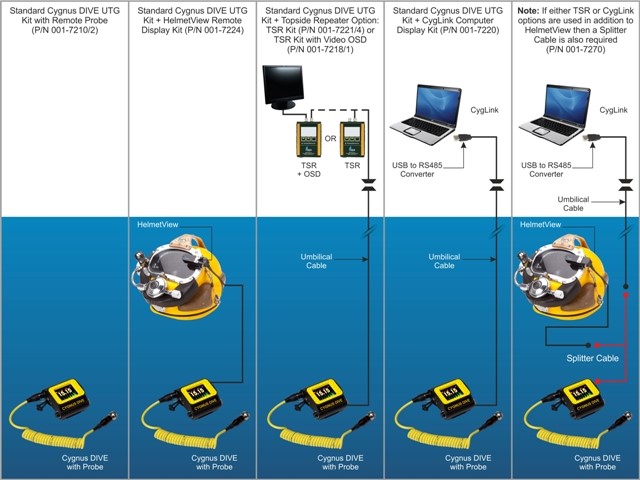

Available with data logging, topside, HelmetView™ and twin crystal probe options.

MSI™ Measurement Stability Indicator – this is a feature exclusive to the Cygnus. When using the DIVE Gauge in Single-Echo and Echo-Echo modes, MSI™ confirms when a reading is stable by turning the thickness measurement numbers from red to yellow.

Cygnus Instruments builds all of its equipment in the UK using only genuine and original parts and components – including Lemo® Connectors and Peli® Cases.

- 300 m depth rated

- Wrist-mountable, giving the diver a free hand

- A-Scan (selectable)

- Data logging – stores 5,000 measurements and A-Scans

- “Auto-Log” – no log button to press

- AMOLED display, easy viewing from all angles for diver and camera

- Multiple-Echo, error- checked measurements through coatings up to 20 mm thick

- Single-Echo – for use on uncoated surfaces with heavy back-wall corrosion/ pitting

- MSI™ Measurement Stability Indicator – exclusive to Cygnus, confirms a stable reading in Single-Echo and Echo-Echo modes

- Echo-Echo – for use on painted surfaces with heavy back-wall corrosion/ pitting (through up to 0.5 mm paint)

- HelmetView™ – optional remote display.

Display | 2.8” quarter VGA colour AMOLED (320 x 240 pixels) Large clear thickness measurement (15 mm high numbers), viewable from all angles A-Scan display with automatic X axis Battery level, signal strength, probe type, velocity Measurement mode and units indication |

Battery | Single 3.6V Li-ion 8.2 W battery 11 hours continuous measurement Low battery warning ‘alert’ message |

Measurement Modes | Multiple-Echo (three back-wall echoes) using Single Crystal (zero-degree) probes automatically ignores surface coatings and measures only metal thickness Echo-Echo (two back-wall echos) using Twin Crystal probes Single-Echo (first back-wall echo) using Twin Crystal probes |

Deep Coat | In Multiple-Echo mode, allows measurement to be made through thicker coatings of suitable materials of up to 20 mm thick |

Accuracy | ±0.1 mm (±0.004”) or 0.1% of thickness measurement, whichever is greatest, when calibrated in accordance with Cygnus Instruments calibration procedure |

Probe Cables | Double outer jacket in tough PU. Coloured yellow for easy locations underwater. Coiled for ease of use. Fischer S105 series connectors. |

Measurement Ranges | Multiple-Echo (through coatings) with Single Crystal probes: 2.25 MHz = 3.0 to 250 mm 3.5 MHz = 2.0 to 150 mm 5.0 MHz = 1.0 to 50 mm Echo-Echo with Twin Crystal probes: 5.0 MHz = 4.0 to 50 mm in steel 2.0 MHz = 6.0 to 50mm in steel Single-Echo with Twin Crystal probes: 5.0 MHz = 2.0 to 100 mm in steel 2.0 MHz = 3.0 to 150 mm in steel |

Measurement Resolution | 0.1 mm – Low resolution mode or measurement >99.95 mm 0.05 mm – High resolution mode and measurement <100.0 mm 0.01 mm – Single-Echo mode only and measurement <100.0 mm |

Measurement Units | mm or inches |

Probe Zero | Fully automatic probe zeroing for all probes types |

V-Path Correction | Automatic V-Path correction for all Twin Crystal probes |

Velocity Range | 2000 to 9000 m/s in 1 m/s setps |

Pulser | Twin channel 70 V spike pulser |

Receiver / Amplifier | 10 MHz bandwidth, 120 dB range, automatic TCG 60 MHz measurement time-base |

Data Logging | One-handed automatic logging of stable measurements. Capacity for up to 5000 points including 640 point A-Scan data. |

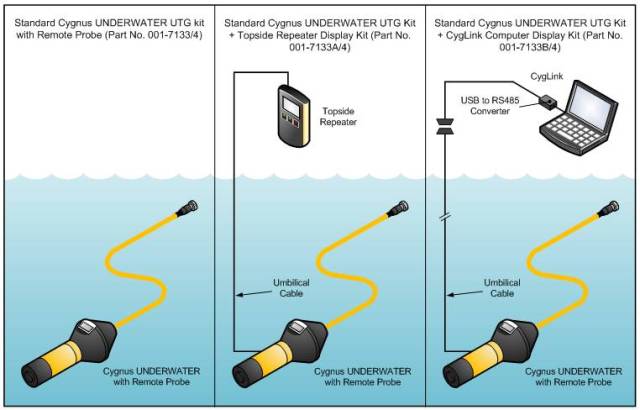

Data Output | RS-485 single pair, half duplex for surface connection |

Computer Software | CygLink v4 allows remote logging and viewing of A-Scan graphs. Survey and report generation to PDF file. Graphic analysis of data and statistical calculations. Designed for Windows 7 and Windows 8. |

- Cygnus DIVE Gauge Body and Wrist Strap

- Ultrasonic Probe(s) with Coiled Cable

- Two Rechargeable Batteries

- Membrane Couplant, 25ml bottle

- Battery Charger and Charger Base

- AC Mains Lead for Battery Charger

- Ultrasonic Couplant Gel (Blue), 100ml bottle

- Test Block 15mm (or ½”) thick in Mil Steel

- Spare Probe Membranes

- Membrane Key

- Silicone Grease, 50g tube

- USB Flash Drive with Documentation

- Calibration Certificate

- Operating Manual

TOPSIDE REPEATER WITH VIDEO OVERLAY

Allows real-time thickness measurements and calibration settings to be overlaid on the dive monitor screen. Also supplied with a hand held repeater unit.

- Measurements superimposed on to a composite PAL or NTSC video signal

- Overlay can be re-positioned anywhere on the screen

- Measurements and locations recorded on the survey video.

SURFACE REPEATER

The Cygnus DIVE can be connected to a laptop on the surface running *CygLink software. This can then be used to log readings and control gauge settings, for example the velocity of sound. Reports and graphical analysis can then be produced and saved.

HELMETVIEW™

Developed by Cygnus for divers in black or limited visibility water. The small remote OLED display is mounted just in front of the lens on the diver’s helmet. With adjustable brightness, the thickness measurement is clearly visible to the diver. When auto-log is being used, the HelmetView™ display will indicate when the reading is logged.

DATA LOGGING

Up to 5,000 measurements and A-Scans can be stored. The “Auto-Log” feature saves each stable measurement meaning the diver doesn’t have to press a button every time a readings needs to be logged. Supplied with CygLink software.

| Single Crystal probes: | 2.25 MHz 13 mm (standard) S2C |

| 2.25 MHz 19 mm S2D | |

| 3.5 MHz 13 mm S3C | |

| 5.0 MHz 6 mm S5C | |

| Twin Crystal probes: | 2.0 MHz 13 mm x2 (for some plastics e.g. outfall pipes) T2C |

| 5.0 MHz 8 mm x2 (standard) T5B |