Phynix Surfix® SX / EX

Modern coating thickness measurement: graphic display, PC connection, easy operation, as well as the proven PHYNIX probes

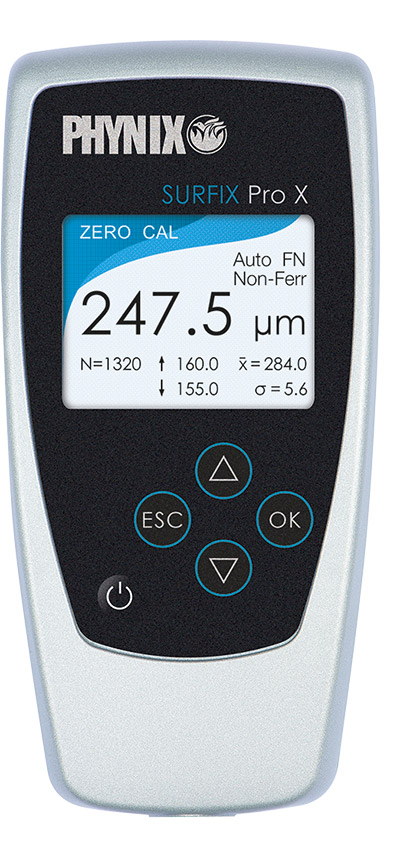

The outstanding feature of this new PHYNIX gauge is the brilliant color graphic display with improved text presentation and allows a variety of different operating languages. The standard now includes English, German, French, Italian, Spanish, Turkish, Czech and Chinese. The internal memory was greatly enlarged compared to the Surfix series and now allows the storage of up to 2,000 measured values. The connection to a computer is simply via USB 2.0. PHYNIX.connect, a data transmission program for all modern Windows systems, facilitates the transfer of measured values into Excel.

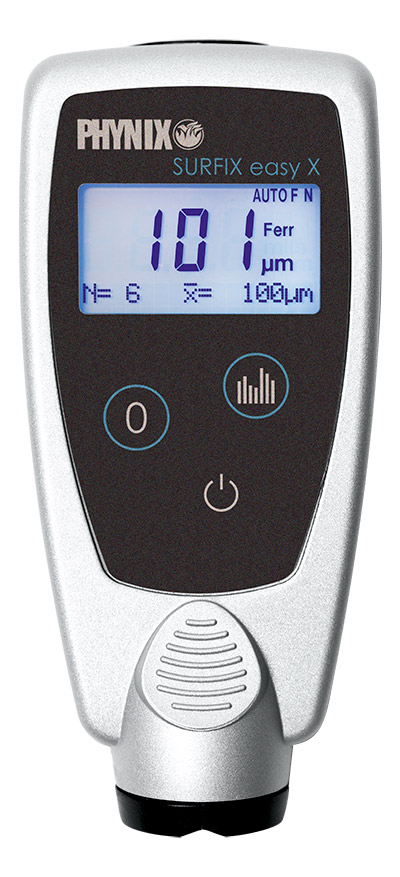

Two models are available: the Surfix® SX can be connected to all probes from the PHYNIX probe program. This ensures the highest possible flexibility which enables the device to fulfill many different measurement tasks. The Surfix® EX devices with the fixed standard probe are suitable for applications where the measurement tasks are clearly defined. It is easy to use and also more cost efficient compared to the Surfix® SX with the high-quality plug-in Connection.

Our Surfix® X gauges are used in the following fields:

- in the electroplating industry

- in the painting industry

- in the automotive industry

- in the chemical industry

- in aerospace engineering

- in shipbuilding

- in research labs and universities

- in the workshop

- for consultants and assessors

- Innovative and user-friendly measurement technology

- High-resolution color graphics display

- USB interface

- Automatic recognition of the base material

- Data memory for up to 2,000 measured values

- Online statistics

- Intuitive menu guidance

- Measurements on hot surfaces up to 150 °C or 300 °C (optional)

- Manufacturer’s test certificate

- 2 years warranty

All our measuring probes have a highly wear-resistant measuring pole made of tungsten carbide and thus have an almost unlimited lifetime.Innovative and user-friendly measurement technologyHigh-resolution color graphics displayUSB interfaceAutomatic recognition of the base materialData memory for up to 2,000 measured values

| Surfix® SX | Surfix® EX | |

|---|---|---|

| Specification | for connection of exchangeable, separate probes (available probe: see separate flyer probes) | external fixed probes |

| Measurement range | depending on the probe | 0 – 1,500 μm |

| Accuracy | depending on the probe up to +/– (0.7 μm + 1 % of reading) | +/– (1 μm + 1 % of reading) |

| Resolution | 0.1 μm or < 0.2 % of reading (with standard probe) | 0.1 μm or < 0.2 % of reading (with standard probe) |

| Calibration method | works calibration, zero calibration, one-foil calibration; zero-offset | works calibration, zero calibration, one-foil calibration; zero-offset |

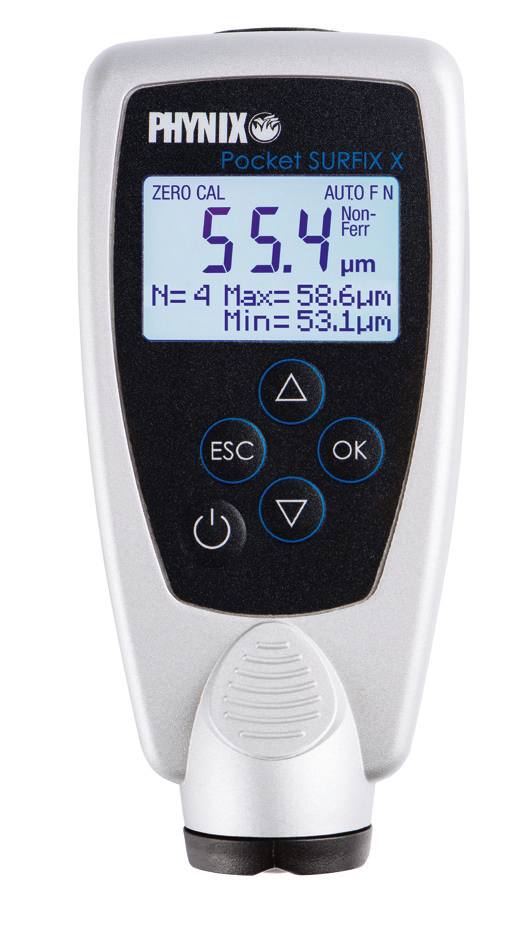

| Statistics | Number of measured values, mean value, standard deviation, minimum and maximum measured value | Number of measured values, mean value, standard deviation, minimum and maximum measured value |

| Memory | max. 2.000 readings | max. 2.000 readings |

| Data transfer | USB 2.0 | USB 2.0 |

| Display | high-resolution color display | high-resolution color display |

| Operating temperature | 0° C to + 50 °C | 0° C to + 50 °C |

| Surface temperature | –15 °C to + 60 °C (standard) –15 °C to + 150 °C or 300 °C (with optional high temperature feet) | –15 °C to + 60 °C (standard) –15 °C to + 150 °C or 300 °C (with optional high temperature feet) |

| Dimensions gauge | 137 mm x 66 mm x 23 mm | 137 mm x 66 mm x 23 mm |

| Weight | 205 g (incl. FN 1.5 probe and batteries) | 205 g (incl. FN 1.5 probe and batteries) |

| Protection class | IP 52 (protection against dust and dripping water) | IP 52 (protection against dust and dripping water) |

| Standards | DIN, ISO, ASTM, BS | DIN, ISO, ASTM, BS |

| Warranty | 2 years | 2 years |

- Gauge

- Protective rubber-cover

- 2 calibration foils

- Zero plate(s) (steel/aluminium)

- 2 batteries AA

- PHYNIX.connect transfer software

- Operating manual

- Manufacturer‘s certificate

- Transport case

The Surfix SX is supplied without a probe. Please choose a probe(s) from our large probe programm and order separately.

- Probes according to PHYNIX delivery program

- Measurement support for precision measurements on small parts

- Calibration standards

- Manufacturer‘s certificate TYP M DIN 55350

- Soft bag

- USB cable