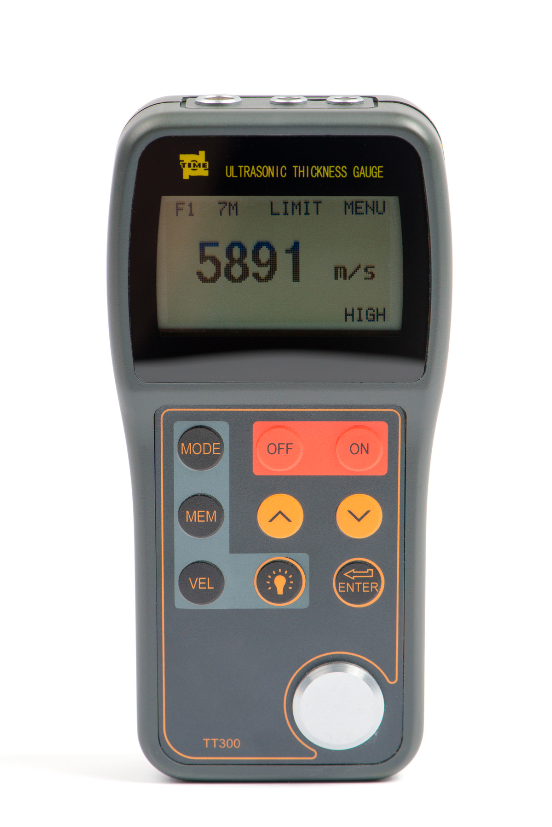

Phynix Wall thickness measurement TT-300 series

Compact Ultrasonic Gauge

The Delta™ TT-300 is a compact ultrasonic gauge designed for Wall Thickness Measurement measurement on metallic and non-metallic materials such as aluminium, titanium, plastic, ceramics and glass. The adjustable measurement frequency allows the connection of specific probes, for example the 10 MHz probe with high detection sensitivity.

Advantages at a glance

Technical specifications

Advantages at a glance

- Easy to operate ultrasonic wall thickness measurement gauge

- Suitable for metals, glass and plastics

- Selectable range of transducers for different applications

- Automatic probe zero adjustment

- Two point calibration possible

- Selectable sensitivity for optimal adjustment to the characteristics of the material

- Display resolution selectable

- 4-digit LCD display with backlight

- Scan mode for minimum thickness measurement

- mm/inch selectable

- RS232-interface

- Large internal memory for 500 readings divided in up to 5 files

- Including rubber protector, couplant and durably aluminium carrying case

Technical specifications

| Measurement range (steell): | 5,0 mm – 300 mm with 2 MHz probe 1,2 mm – 225 mm with 5 MHz probe 0,75 mm – 25 mm with 10 MHz probe |

| Measurement range for tubes (steel): | min. Ø 20 mm, min. wall thickness 3 mm |

| Resolution: | selectable: low 0.1 mm or high 0.01mm |

| Tolerance: | 0.05 mm for thicknesses up to 9.99 mm (0.5%+0.01) mm for thicknesses up to 99.99 mm (1%+0.1) mm for thicknesses up to 300 mm |

| Measurement units: | Selectable: mm or inch |

| Sound velocity range: | 1000 to 9999 m/s |

| Display: | 4-digit LCD with backlight (selectable) |

| Alarm function: | Minimum / Maximum limits exceeding alarm |

| Data memory: | Storage of 500 thickness readings, devided in up to 5 files |

| Interface: | RS232 |

| Surface temperature: | Standard -15°C to +60°C, (high temperature probes available) |

| Dimensions: | 152 mm x 74 mm x 35 mm |

| Weight: | 370g (incl. batteries) |

| Power supply: | 2 pcs. 1.5 V, AA batteries |

| Operating time: | With backlight 60 hours, without backlight 150 hours |

Scope of delivery

Scope of delivery

- Main unit Delta TT-300

- Probe 5 MHz with cable

- Batteries AA (2 pcs.)

- Rubber protector

- Couplant

- Instruction manual

- Manufacturer’s certificate

- Aluminium carrying case