CYGNUS 4 PLUS GENERAL PURPOSE

- Multiple-Echo mode for accurate, through-coat measurements as specified by Classification Societies

- Echo-Echo and Single-Echo modes for heavily corroded metals with a thin or no coating

- Deep Coat function ignores coatings up to 20mm thick

- Manual and automatic gain control

- Min/max measurement limit functions with visual and vibrate alert

- Large front sunlight readable LCD display with Live A-scan

- Water and dust tight IP67 housing

- Shock and impact proof to US MIL STD 810G

- Safe operation in explosive atmospheres: Class 1, Division 2, Group D locations only, as defined in NFPA 70, Article 500

- One and two point calibration

- Can be upgraded to 6+ at an additional cost.

| Measuring Modes | Multiple-Echo using 3 echoes to ignore coatings up to 20 mm (0.8 inch) thick Echo-Echo using 2 echoes to ignore coatings up to 1 mm (0.04 inch) thick Single-Echo using 1 echo |

| Materials | Velocities from 1,000 – 9,000 m/s (0.0390 – 0.3543 in/us) |

| Accuracy | ±0.05 mm (±0.002 inch) – in Multiple-Echo measurement mode, when calibrated and measuring the same material as calibrated on ±0.1 mm (±0.004 inch) or 0.1% of thickness measurement whichever is the greatest – in Single-Echo & Echo-Echo measurement modes, when calibrated and measuring the same material as calibrated on |

| Resolution | Multiple-Echo mode – 0.1 mm (0.005 inch) or 0.05 mm (0.002 inch) Single-Echo and Echo-Echo modes – 0.1 mm (0.005 inch) or 0.01 mm (0.001 inch) |

| Probe Options | Single crystal probes, Twin crystal probes and High temperature probe |

| Measurement Range in Steel | 0.8 – 250 mm (0.031 – 10 inch) depending on selected probe and configuration, material and temperature |

| Connector | 2 x Lemo 00 |

| Power | 3 x AA / R6 batteries |

| Battery Life | Approx. 10 hours continuous measurement |

| Electronics | Dual channel pulser |

| Display | 2.4 inch QVGA LCD: 47 x 37 mm |

| Size | 84 x 130 x 35 mm (3.3 x 5.1 x 1.4 inch) |

| Weight | 300 g (10.5 oz) (inc. batteries) |

| Operating Temp. | -10°C to 50°C (14°F to 122°F) |

| Data Logging | 5,000 measurements and A-scans per record. Max number records: 100 (soft limit) |

| Computer Software | CygLink allows remote logging and viewing of A-scan graphs Survey and report generation to PDF file Graphic analysis of data and statistical calculations |

| Environmental Rating | IP67 Safe operation in Explosive Atmospheres: Class I, Division 2, Group D Locations only, as defined in the National Fire Protection Association Code (NFPA 70), Article 500. Tested using MIL-STD-810G, Method 511.5, Procedure I MIL STD 810G Method 501.6 (high temp +55°C (131°F)) MIL STD 810G Method 502.6 (low temp -20°C (-4°F)) MIL STD 810G Method 507.6 (humidity 95%) MIL STD 810G Method 512.6 (immersion 1 metre for 30 mins) |

| Shock and Impact | MIL STD 810G Method 514.7 (vibration) MIL STD 810G Method 516.7 (shock 20g) MIL STD 810G Method 516.7 (transit drop 1.22 m) |

| Standards | Designed for EN 15317 |

| Compliance | CE, UKCA, RoHS |

| Warranty | 3 years on gauge and 6 months on probe |

The Cygnus 4+ General Purpose High Temperature Kit comes with Probe T5B-MAUH 5MHz Twin Element & Twin Lemo 00 to Microdot Lead (050-4502/5)

| Weight | 5 kg |

| Kit | Cygnus 4+ General Purpose Standard Kit WITHOUT PROBE (050-4500/5), Cygnus 4+ General Purpose High Temperature Kit (050-4502/5) |

To compliment our ultrasonic thickness gauges we offer a range of ultrasonic probes. The performance of any ultrasonic thickness gauge relies heavily on the probe and its suitability to the material being measured. Therefore, selecting the right probe is vital. All Cygnus’ probes are made from stainless steel and have a hard wear face or a wear membrane to protect the probe.

Variety of Cygnus INOX Probes

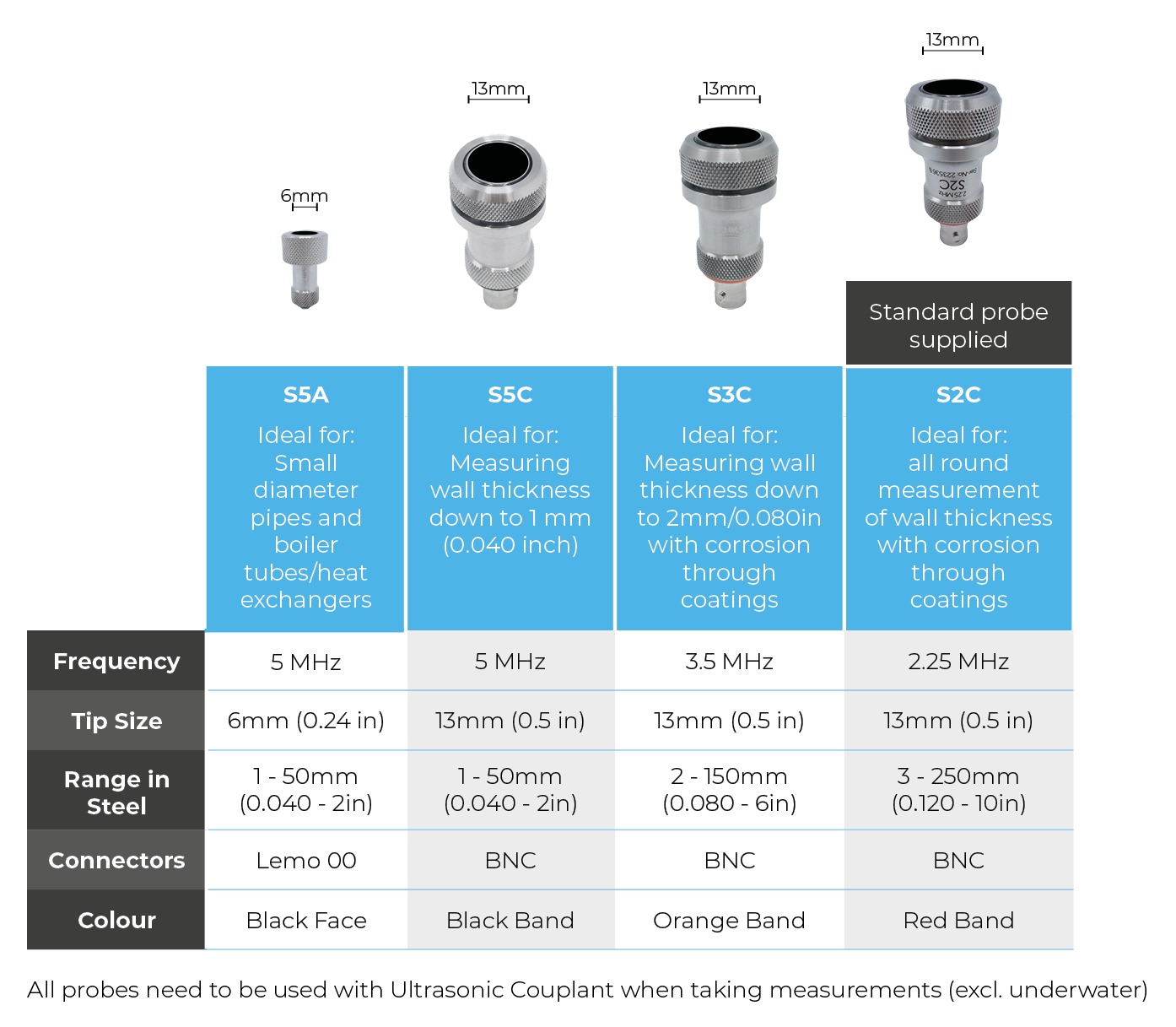

- Stainless steel SINGLE CRYSTAL probes, used in multiple-echo mode, include replaceable membranes for long life, require no zeroing and have a high linear accuracy.

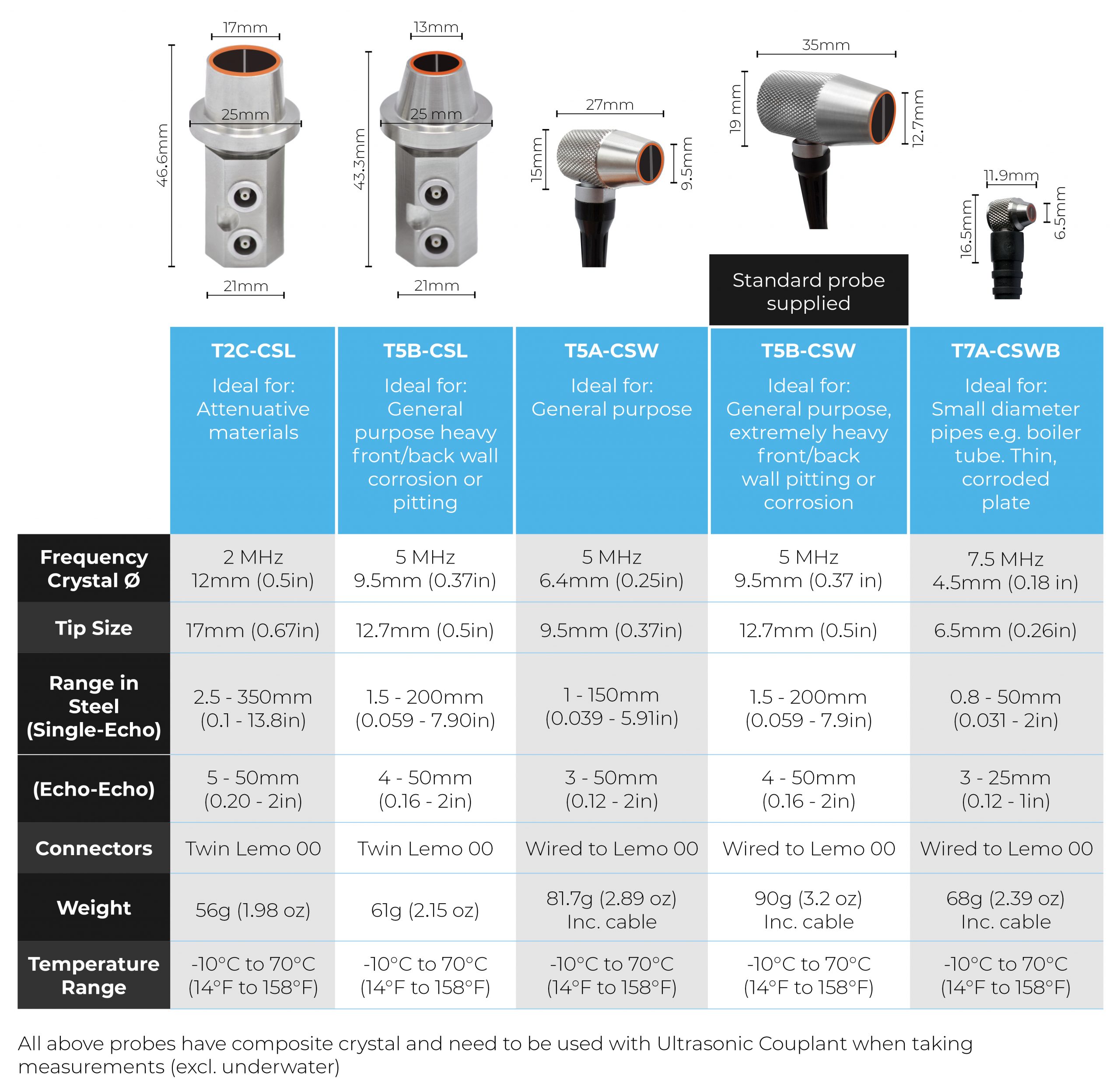

- Stainless steel TWIN CRYSTAL probes, used in echo-echo and single-echo modes, have improved measurability on extreme back wall corrosion and pitting.

- Probes for use with the Cygnus 2+, 4, 4+ and 6+ gauges are fitted with a BNC or Lemo 00 connector.

Single Crystal Probes

Twin Crystal Probes

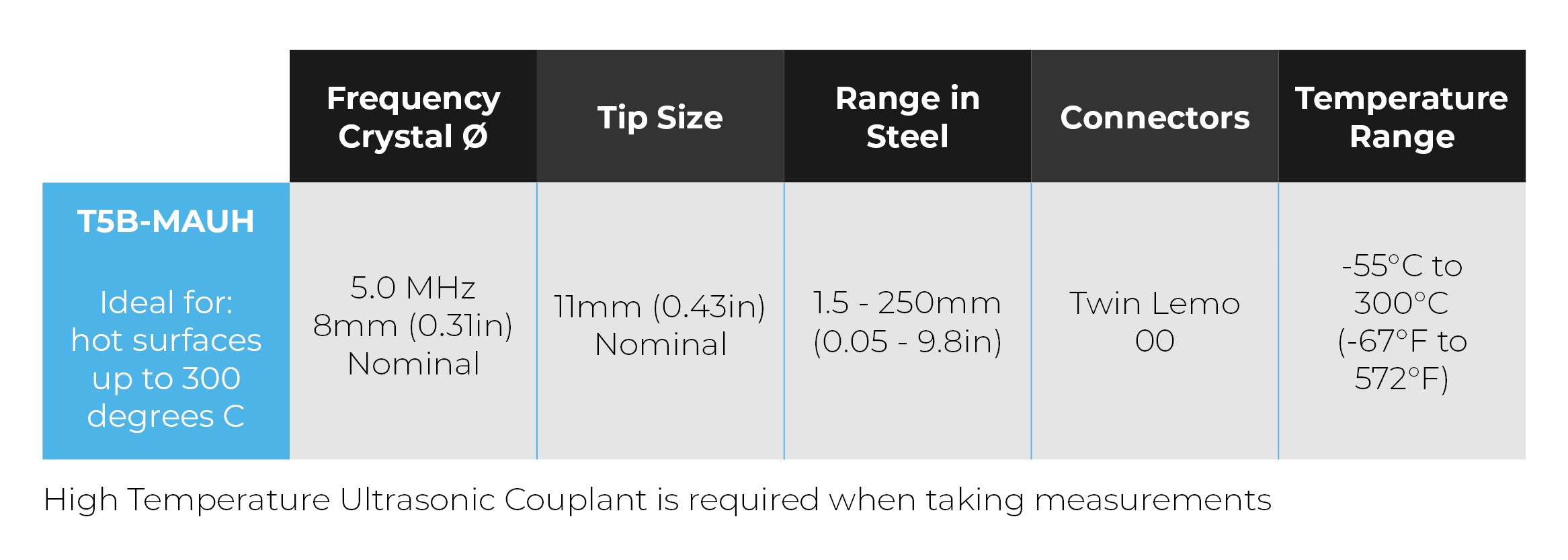

High Temperature Probe

Twin element ultrasonic probe designed for high-temperature, in-service thickness measurements and corrosion surveys across oil & gas, refining, energy and process sectors.

- No cooling period required – reducing inspection time and facilitating effective measurement

- For use on hot surfaces up to 300°C

- Measures remaining wall thickness from 1.5 to 250 mm (0.05 to 9.8 inch) – depending on temperature and material.