There are two ways CygLink is used with the Cygnus DIVE gauge:

- Logging on a computer at the surface

- To upload readings from a data logging DIVE gauge.

Surface Repeater

A DIVE ultrasonic thickness gauge can be connected to a computer on the surface with an umbilical cable. With the computer running CygLink, thickness readings and A-scans taken by the gauge can be logged on the computer at the surface.

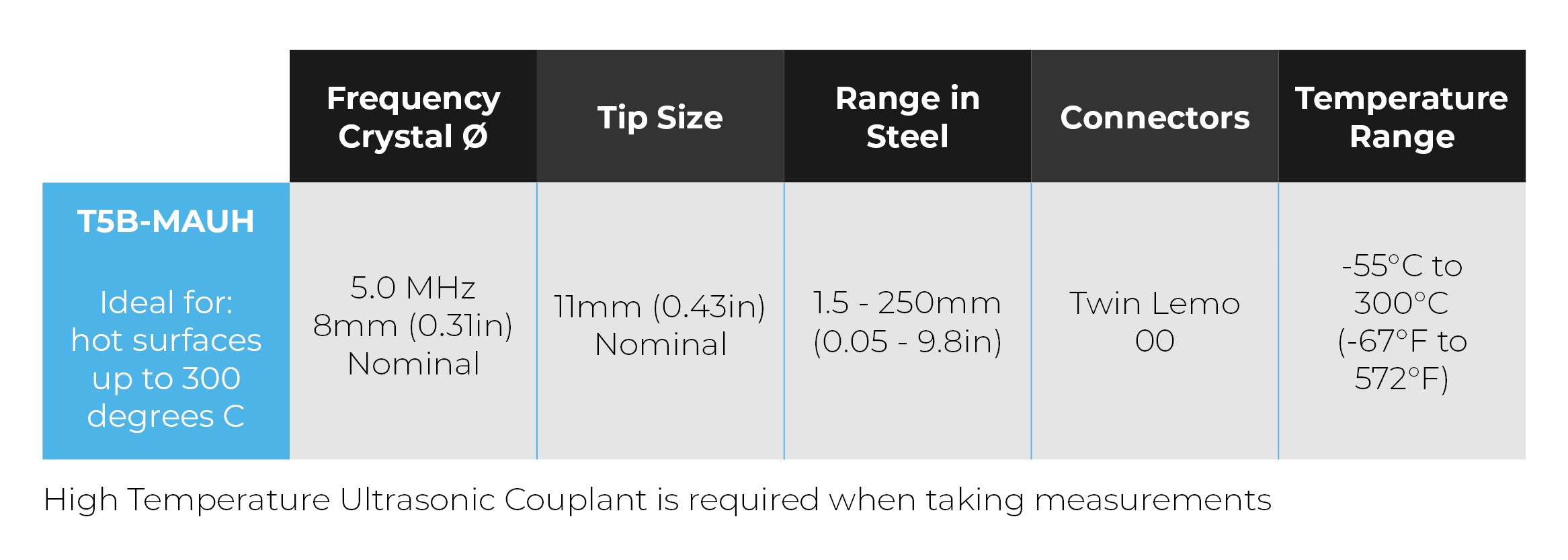

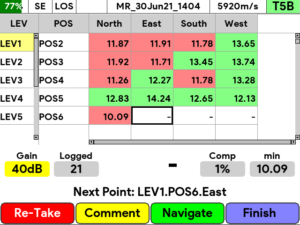

Thickness measurements can be logged either as a linear list or a two dimensional grid. Reference (original material thickness) and Minimum Thickness Criteria can be set and any measurement below the minimum will be highlighted as red. Comments and notes can be added to each thickness measurement and there is the facility for 8 pre-set comments to be set-up for convenience.

Gauge settings, including the velocity of sound can be controlled from the surface. The software used in this way provides the following functionality:

- Surface display of thickness measurements

- Surface display of A-scan and B-scan graph

- Logging of the measurement, A-scan and B-scan

- Surface display of the gauge’s battery level

- Remote setting of the velocity of sound

- Remote setting of the units (metric or imperial) Remote control of the Deep Coat function

- Estimation of thickness from A-scan graph and data logging of this estimated thickness value.

Once logged in CygLink the measurements (and A-scans and B-scans if applicable) can be viewed and analysed. The information can then be printed as a .pdf report or exported to a .csv file.

Cygnus DIVE Computer Logging Kit Contents:

- 9-way D to USB link lead.

- Fischer to 9-way D connector (this connect the DIVE Gauge which has a Fischer connector to umbilical cable with a 9-way D Connector fitted).

- CygLink software supplied on a USB stick (this is also available to download from the “Technical Software” list in the Support section of our website http://www.cygnus- instruments.com/support. Please either log-in or register with an email address and password to access it.

- An umbilical cable is required to connect the DIVE gauge to the computer at the surface. Cygnus can supply the complete umbilical cable with connectors fitted, or the customer can make their own umbilical cable using connectors supplied with cable tails.

- Cygnus umbilical cable P/N 001-0415.

Data Logging DIVE Thickness Gauge

If the DIVE gauge is a data logging model, measurements can be logged into the gauge memory during the underwater survey. When the gauge is at the surface it is connected to a computer with a USB to Fischer cable (supplied in the gauge kit), and the readings are then uploaded into the CygLink software installed on a computer.

Once in CygLink the readings (and A-scans and B-scans if applicable) can be viewed and analysed. The information can then be printed as a .pdf report or exported to a .csv file.