Ultrasonic Thickness Measurements

– is a nondestructive testing (NDT) for hull structures.

It is performed to ensure that global & local vessel strength is retained. Check internal condition and remaining thickness of a vessel. Ascertain all possible areas of concern in terms of thickness measurement and close up requirements for all types of vessels.

Thickness measurements can be obtained when the vessel is in or out of operation (pre-docking or dry-docking) and is performed by qualified inspectors. Preparation of accurate and reliable report based on information from measurements, which further used for designing and budgeting repair works.

Our technicians are highly experienced and qualified in this area of work as well as in many other related areas, such as: steel supervising, photo reporting, visual inspection, and pre-purchase inspection, steel weight calculation/estimation and others.

UTM surveys we conduct:

UTM for Class Surveys (all types, incl. ESP Vessels)

UTM Shipping Service can assist through all the stages:

- Preparation of document and planning

- Organization of the ballast / survey program

- Completion of UTM requirements to Class rules and accompanying the Class surveyor if required

- Carrying out ultrasonic thickness measurement survey

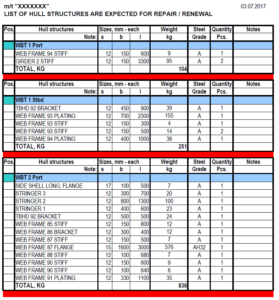

- Creation of a steel renewal report to cover any areas of substantial or renewable wastage

- Provide supervision of repairs at the shipyard if required

UTM for Owner’s Condition Survey

- With UTM surveys being such a major part of the special / intermediate / CAP and CAS surveys we are able to assist the owner or managers to reduce the pressure on them by taking a big lump of organization/preparation/supervision jobs

- When vessel is being sold or bought (independent/neutral to both parties company) for fair assessment of vessel condition

UTM for CAP and CAS Surveys

- Pre Docking Assessments, Work Scope Forecasting, Budgeting, Dry Dock Planning

- Class Reporting as per ABS, BV, LR, NKK, DNV-GL, RINA, INSB and RS

- CAP & CAS. Reporting

- Repair Supervision, Verification of Final Work Done

- Pre-Purchase Inspections

- Comprehensive Vessel Inspection Program

- Surveys can range from a few hundred readings on a small vessel up to 60.000 for a large vessel with CAP or CAS requirements

- All our inspectors have years of experience conducting ultrasonic thickness measurement (UTM) surveys and are all qualified to minimum EN ISO 9712 level 2

UTM for Class Surveys (all types, incl. ESP Vessels)

UTM Shipping Service can assist through all the stages:

- Preparation of document and planning

- Organization of the ballast / survey program

- Completion of UTM requirements to Class rules and accompanying the Class surveyor if required

- Carrying out ultrasonic thickness measurement survey

- Creation of a steel renewal report to cover any areas of substantial or renewable wastage

- Provide supervision of repairs at the shipyard if required

UTM for Owner’s Condition Survey

- With UTM surveys being such a major part of the special / intermediate / CAP and CAS surveys we are able to assist the owner or managers to reduce the pressure on them by taking a big lump of organization/preparation/supervision jobs

- When vessel is being sold or bought (independent/neutral to both parties company) for fair assessment of vessel condition

UTM for CAP and CAS Surveys

- Pre Docking Assessments, Work Scope Forecasting, Budgeting, Dry Dock Planning

- Class Reporting as per ABS, BV, LR, NKK, DNV-GL, RINA, INSB and RS

- CAP & CAS. Reporting

- Repair Supervision, Verification of Final Work Done

- Pre-Purchase Inspections

- Comprehensive Vessel Inspection Program

- Surveys can range from a few hundred readings on a small vessel up to 60.000 for a large vessel with CAP or CAS requirements

- All our inspectors have years of experience conducting ultrasonic thickness measurement (UTM) surveys and are all qualified to minimum EN ISO 9712 level 2

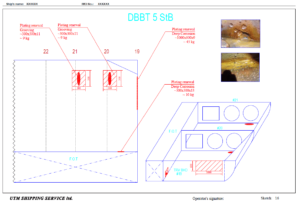

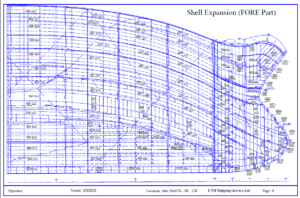

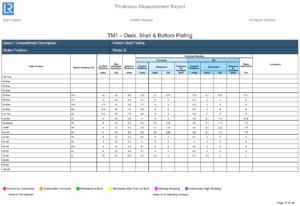

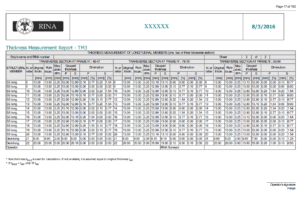

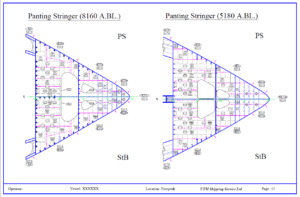

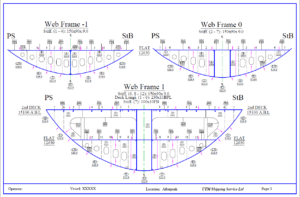

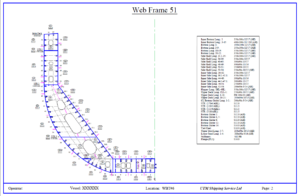

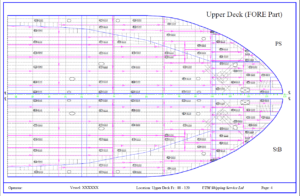

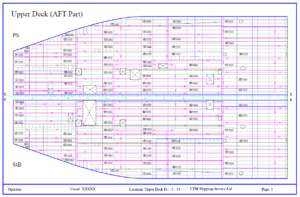

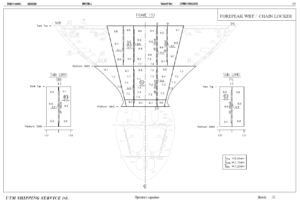

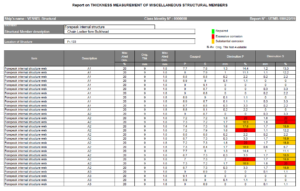

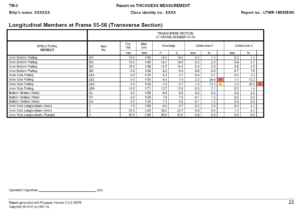

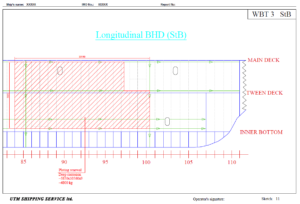

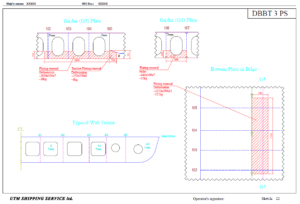

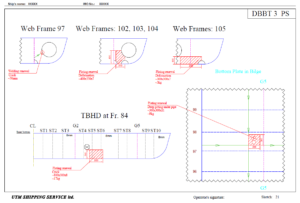

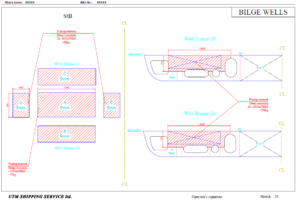

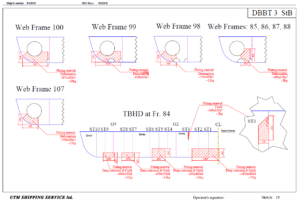

Report drawings and tables examples

Statistics

Additional Services

UTM Shipping Service Ltd can also provide Tightness testing, Nondestructive testing (MT, PT, VT, UT, ET) and Training Courses for Cygnus Hatch Sure equipment needed for Tightness Testing (Leak Detection) and much more.

Founders

Our team is well trained and experienced in this field of work. The specialists are highly qualified, certified according to EN ISO 9712 and SNT-TC-1A (UT / VT / MT / PT / ET Level II and Level III) and equipped with modern portable devices.

Andrei Junajev

Co-founder, CEO & UTM Technician/Operator (certificate level II) at UTM Shipping Service Ltd.

Anton Junajev

Co-founder, Operations Director & UTM Technician/Operator (certificate level II) at UTM Shipping Service Ltd.

Get our

price list

Work Blog

USA: Miami, Norfolk, New York, Los Angeles

Singapore:

Japan: Nagoya, Tokyo

United Kingdom: Newcastle, Aberdeen, Southampton, Dorchester, Workington

France: Brest

Germany: Hamburg, Kiel, Rostock, Husum

Russia: St. Petersburg

China: Hangzhou

Greece: Athens

Cyprus: Nicosia

Belgium: Zeebruge

Estonia: Tallinn, Maardu, Sillamae

Latvia: Riga, Ventspils, Liepaja

Lithuania: Klaipeda

Mauritania: Nouadhibou

Portugal: Lisbon

Spain: Malaga, Valencia, Barcelona, Las Palmas, Algeciras

Finland: Helsinki, Tornio, Turku, Naantali

Sweden: Stockholm, Malmo

Norway: Haugesund, Oslo, Bergen, Tromso, Stavanger, Leknes, Skjersholmane

Iceland: Reykjavik

Netherlands: Amsterdam, Rotterdam

Denmark: Allborg, Kalundborg, Vejle, Copenhagen

Poland: Gdynia, Swinoujscie, Gdansk, Szczecin

Gibraltar:

Bulgaria: Varna

Turkey Istanbul, Tuzla

U.A.E: Dubai

Egypt: Cairo, Suez

Bahrain:

Lebanon: Beirut

Morocco: Dakhla, Agadir, Casablanca

Cuba: Havana

RSA: Cape Town

Uruguay: Montevideo

Mexico: Mexico city, Zihuatanejo

St. Lucia: Castries

Brazil: Rio

Colombia: Bogota, Barranquilla

Panama: Colon

Sri Lanka: Colombo

Ghana: Tema, Accra

Benin: Cotonou

Get In touch

Contact us

Marketing & Sales Management: +372 58 83 72 74 Technical Management: +372 53 03 63 99

Visiting address:

Sõstramäe 12 – 39, 11415 Tallinn, ESTONIA